I have started on a plinth for my SP10. It has been rather slow going as I have not really had solid windows of time to work on this project....

I am using Kiaat (again - I have lots taking up space in the garage)... The twist this time are some decorative inserts of Oak and Panga Panga.

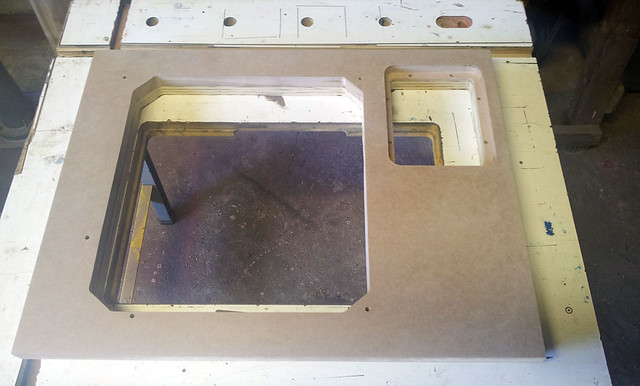

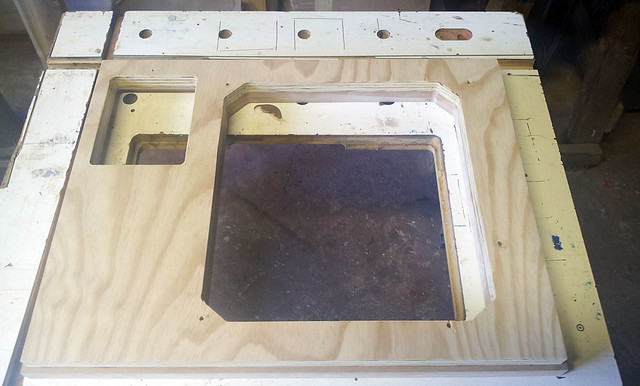

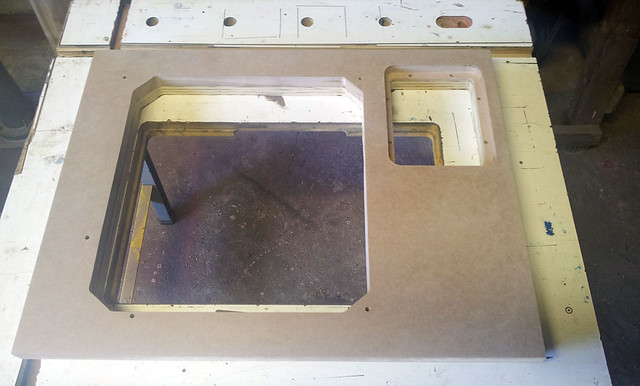

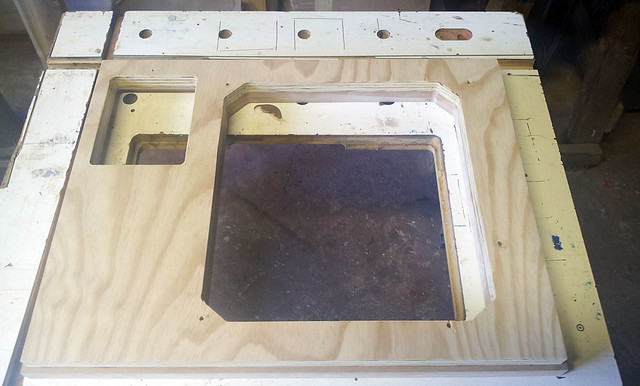

For the top I am using a mix of 22mm MDF and 18mm ply for strength (and incidental constrained layer damping).

The bottom will be removable and the plinth will have removable/interchangeable armboards...

Here are some pics of the progress thus far.

Technics SP-10 Mk2 Plinth Build - topside by arclients, on Flickr

Technics SP-10 Mk2 Plinth Build - underside by arclients, on Flickr

Technics SP-10 Mk2 Plinth Build - inside recess by arclients, on Flickr

Technics SP-10 Mk2 Plinth Build - inserts by arclients, on Flickr

Technics SP-10 Mk2 Plinth Build - cross-section by arclients, on Flickr

This is the first time i am trying inserts so cut me some slack if they are a little uneven.

BTW. Panga-Panga is friggin hard stuff!! ??? :

: I cut the recess for the inserts and then sandwiched the panga panga between the oak strips and glued them into the Kiaat. Once dried I flattened the inserts with a belt sander. The belt sander took strain going through 2mm thick Panga Panga.... What did please me though, is that my Festool cut through the Panga-Panga (Wenge) with minimal strain...

I cut the recess for the inserts and then sandwiched the panga panga between the oak strips and glued them into the Kiaat. Once dried I flattened the inserts with a belt sander. The belt sander took strain going through 2mm thick Panga Panga.... What did please me though, is that my Festool cut through the Panga-Panga (Wenge) with minimal strain...

I am using Kiaat (again - I have lots taking up space in the garage)... The twist this time are some decorative inserts of Oak and Panga Panga.

For the top I am using a mix of 22mm MDF and 18mm ply for strength (and incidental constrained layer damping).

The bottom will be removable and the plinth will have removable/interchangeable armboards...

Here are some pics of the progress thus far.

Technics SP-10 Mk2 Plinth Build - topside by arclients, on Flickr

Technics SP-10 Mk2 Plinth Build - underside by arclients, on Flickr

Technics SP-10 Mk2 Plinth Build - inside recess by arclients, on Flickr

Technics SP-10 Mk2 Plinth Build - inserts by arclients, on Flickr

Technics SP-10 Mk2 Plinth Build - cross-section by arclients, on Flickr

This is the first time i am trying inserts so cut me some slack if they are a little uneven.

BTW. Panga-Panga is friggin hard stuff!! ???