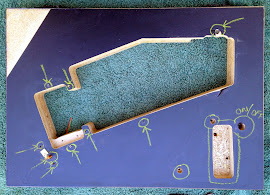

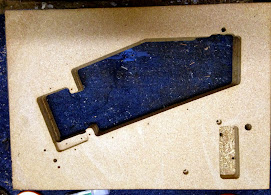

I picked up this old Telefunken direct drive, which turned out to be an all Technics internals machine, with a very nice and solid OEM Japanese tonearm. The motor ran on speed, and the tonearm bearings were A-OK. Unfortunately the black vinyl veneer had seen better days, and made the deck look cheap and tatty. Fortunately the basic plinth was solid and in great shape. So I chatted to my neighbour Akomeogi, on the forum, to get some tips, and decided to veneer. The auto-return was broken, so I removed all of that as well (and I prefer it that way, to be honest). I also fitted a new push-button on/off switch, bought from Yebo.

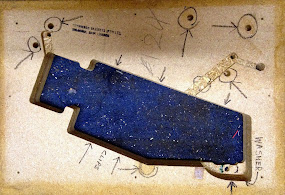

I got the Kiaat veneer from Davidson's Manufacturing in Epping, and their staff and service, as well as their price, were all astonishingly good - thanks Ladies! I used Genkem contact adhesive, and all the trimming was done with a trimming bit fitted to my Elu router, fitted to a router table. The finish is 4 coats of Woodoc 10 Polywax sealer, with light sanding between coats 1 - 3.

Thereafter it was time, effort, patience and more patience. It is not finished yet, but tonight I assembled the deck and am now listening to some great jazz on the stunning little table!

Now listening to "Sorrow is not forever - Love is" - sounds great!

(and I have another one of these!)

I got the Kiaat veneer from Davidson's Manufacturing in Epping, and their staff and service, as well as their price, were all astonishingly good - thanks Ladies! I used Genkem contact adhesive, and all the trimming was done with a trimming bit fitted to my Elu router, fitted to a router table. The finish is 4 coats of Woodoc 10 Polywax sealer, with light sanding between coats 1 - 3.

Thereafter it was time, effort, patience and more patience. It is not finished yet, but tonight I assembled the deck and am now listening to some great jazz on the stunning little table!

Now listening to "Sorrow is not forever - Love is" - sounds great!

(and I have another one of these!)