Hi Gents,

This project has been commissioned by a customer of mine and he has agreed that the photos be shared.

I need to make a chassis for a PALADIN SM-150 stereo amplifier, and this here will document the machining of the heatsinks.

I need 2x heatsinks sized around 410mm wide x 150mm tall x 40mm deep, so we start with some aluminium plate. In this case it's 6082 T651 grade manufactured by Hulamin. Out of interest - 6082 grade is the strongest of the 6000 grade family - stronger even than the venerable 6061 grade. Because it's so strong it machines very well (doesn't gum up too much like the softer types) and can achieve a good surface finish. It is commonly referred to as a structural grade of aluminium.

If you want more information on this grade of aluminium, please check here: http://www.aalco.co.uk/datasheets/Aluminium-Alloy-6082-T6T651-Plate_148.ashx

I only needed the 2 heatsinks, but I always make sure I have an "insurance" piece - just incase something goes wrong

https://lh3.googleusercontent.com/qTkxVies2YgdtTwMDoczkijK2FgvFtUXYmHQqSVAbyNwepsf5gZ-

7lMOg69SZFeDzZfPsJ375w6S3NyTstfR0JZJCfviM7smgVelAIqrD_U060j1kt578ZpzKlmEmCadLLN7xe7iN0eCIOOmri71IXaxggHhG65C-i_BWOfPZ2fWUtIhQh3KnLD8b4H8Wp0EBvRNw9_CiOs9sH2wJT2p57U1IK9bcIDO4BZpyxgfvtY7VZKBcxeAfuWPZHMeFnkwgA8-X8wmhBYE1gZfw9LoN2e6N_VrV53_e8nJRWOs6bRdFX1MBnAzf2n0qyXQVlMebxkih2_bCgxcZKFo7_-HPwNSyQ6vog3h24tKiyKfyjtDAu0VfNcnLgJxwwGHeUn3Dstdlg_4c7sCUaPW7GpbSVd--BEK1Jr4bXmpoCHmhTPyWgS8-vhylVq7MOihprKy0yWcNaQGL-q4XKN6ygvyKsrkmEPw69rVTANHZWl6IABfVPuU7Y8C0jGKHmXNN_JbYSTbhjqbsbLlGmpTmTQFarf0HfdFbGAAVgDQLAUhQHFXbx71smCU0Q-D3m0GEf1y8O6k5DOJJ2m1syFNWZZokfloSp3VPDA10RU5H1_YyZnu2TaDYsR8dPoe_RoqgIMr_cZqu0u91E-50-qNZTwaGk_RIGtEEynAZLZsSJ-R3g=w996-h490-no

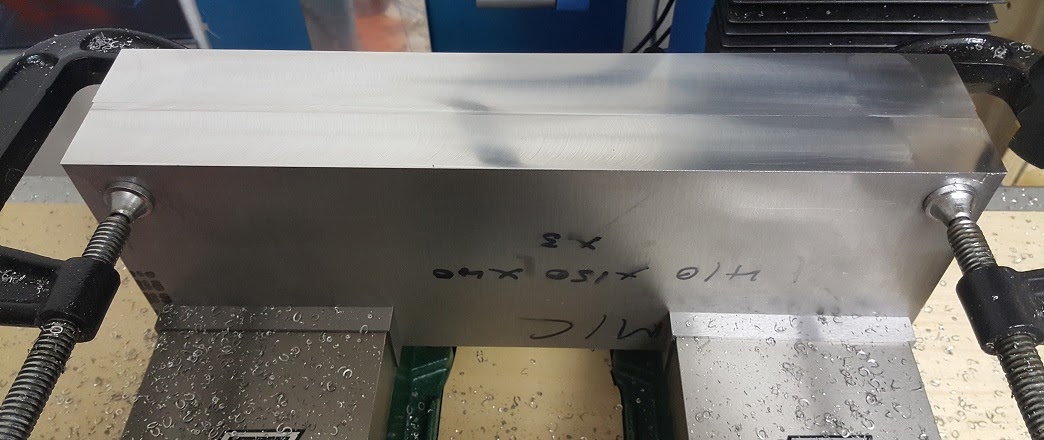

Some nice big pieces of plate. Aluminium is pretty light-weight, but I promise you that those slabs are anything but light...

I need to mill the slabs to size and square the sides up. The long sides are machined first using a face-mill. This is the before and after photos:

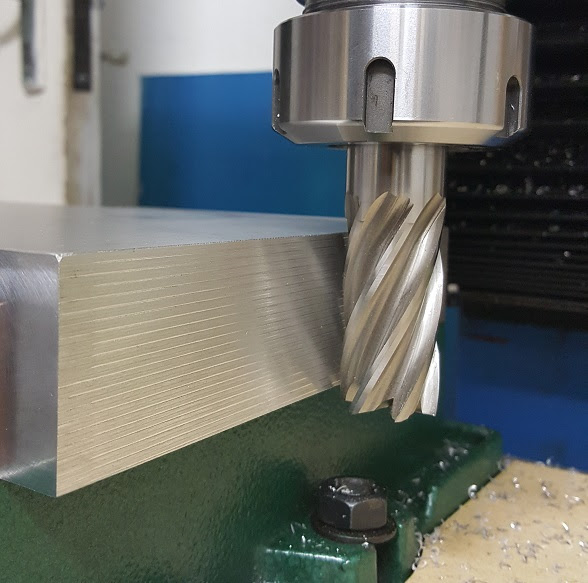

After both sides (top and bottom) have been milled I flip the pieces in the vice and mill the sides. This is the before and after photos. The end-mill you see in these pictures is a 25mm diameter, 6 flute monster. Why use such a big cutter? Because I don't want it to flex while cutting the entire 40mm thickness in a single pass. Thinner end mills will also work, but you would need to take additional "spring passes".

These are the chips coming off the 25mm end mill:

Kind regards,

Ian.

This project has been commissioned by a customer of mine and he has agreed that the photos be shared.

I need to make a chassis for a PALADIN SM-150 stereo amplifier, and this here will document the machining of the heatsinks.

I need 2x heatsinks sized around 410mm wide x 150mm tall x 40mm deep, so we start with some aluminium plate. In this case it's 6082 T651 grade manufactured by Hulamin. Out of interest - 6082 grade is the strongest of the 6000 grade family - stronger even than the venerable 6061 grade. Because it's so strong it machines very well (doesn't gum up too much like the softer types) and can achieve a good surface finish. It is commonly referred to as a structural grade of aluminium.

If you want more information on this grade of aluminium, please check here: http://www.aalco.co.uk/datasheets/Aluminium-Alloy-6082-T6T651-Plate_148.ashx

I only needed the 2 heatsinks, but I always make sure I have an "insurance" piece - just incase something goes wrong

https://lh3.googleusercontent.com/qTkxVies2YgdtTwMDoczkijK2FgvFtUXYmHQqSVAbyNwepsf5gZ-

7lMOg69SZFeDzZfPsJ375w6S3NyTstfR0JZJCfviM7smgVelAIqrD_U060j1kt578ZpzKlmEmCadLLN7xe7iN0eCIOOmri71IXaxggHhG65C-i_BWOfPZ2fWUtIhQh3KnLD8b4H8Wp0EBvRNw9_CiOs9sH2wJT2p57U1IK9bcIDO4BZpyxgfvtY7VZKBcxeAfuWPZHMeFnkwgA8-X8wmhBYE1gZfw9LoN2e6N_VrV53_e8nJRWOs6bRdFX1MBnAzf2n0qyXQVlMebxkih2_bCgxcZKFo7_-HPwNSyQ6vog3h24tKiyKfyjtDAu0VfNcnLgJxwwGHeUn3Dstdlg_4c7sCUaPW7GpbSVd--BEK1Jr4bXmpoCHmhTPyWgS8-vhylVq7MOihprKy0yWcNaQGL-q4XKN6ygvyKsrkmEPw69rVTANHZWl6IABfVPuU7Y8C0jGKHmXNN_JbYSTbhjqbsbLlGmpTmTQFarf0HfdFbGAAVgDQLAUhQHFXbx71smCU0Q-D3m0GEf1y8O6k5DOJJ2m1syFNWZZokfloSp3VPDA10RU5H1_YyZnu2TaDYsR8dPoe_RoqgIMr_cZqu0u91E-50-qNZTwaGk_RIGtEEynAZLZsSJ-R3g=w996-h490-no

Some nice big pieces of plate. Aluminium is pretty light-weight, but I promise you that those slabs are anything but light...

I need to mill the slabs to size and square the sides up. The long sides are machined first using a face-mill. This is the before and after photos:

After both sides (top and bottom) have been milled I flip the pieces in the vice and mill the sides. This is the before and after photos. The end-mill you see in these pictures is a 25mm diameter, 6 flute monster. Why use such a big cutter? Because I don't want it to flex while cutting the entire 40mm thickness in a single pass. Thinner end mills will also work, but you would need to take additional "spring passes".

These are the chips coming off the 25mm end mill:

Kind regards,

Ian.