I looked online to find a suitable power cord connector system with male/female that could work for any of my power tools. I have one Festool power tool with its own proprietary ?Plug-it? quick change system, but that would not work on other branded tools and anyway even if it could, the cost would make it prohibitively expensive.

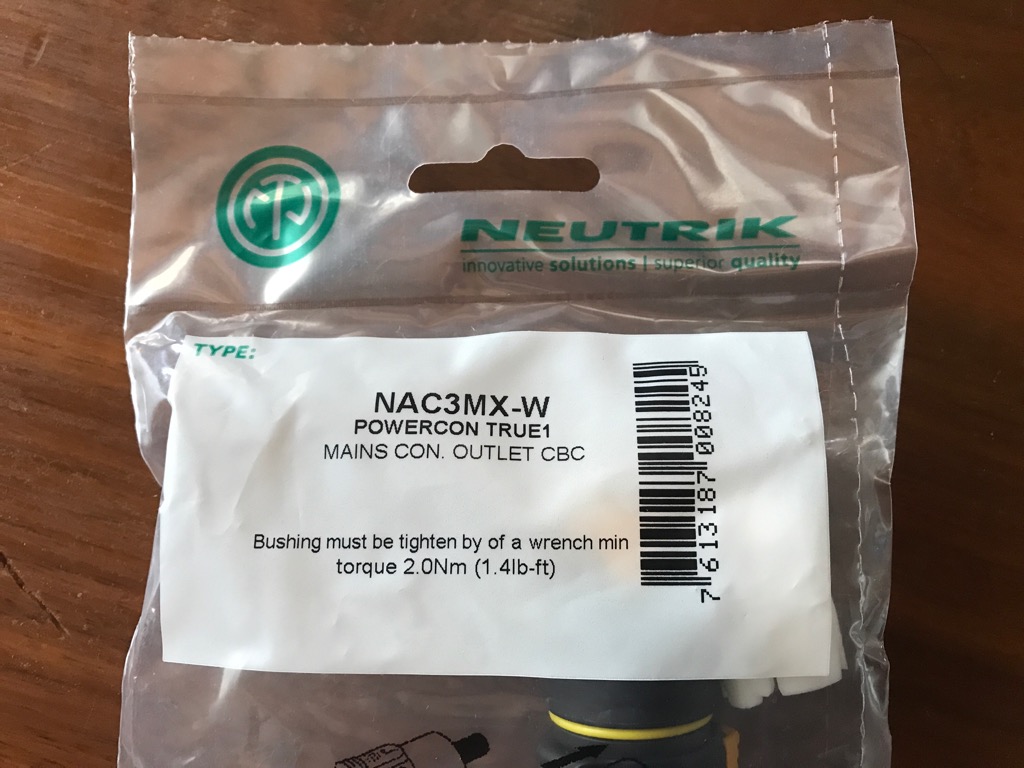

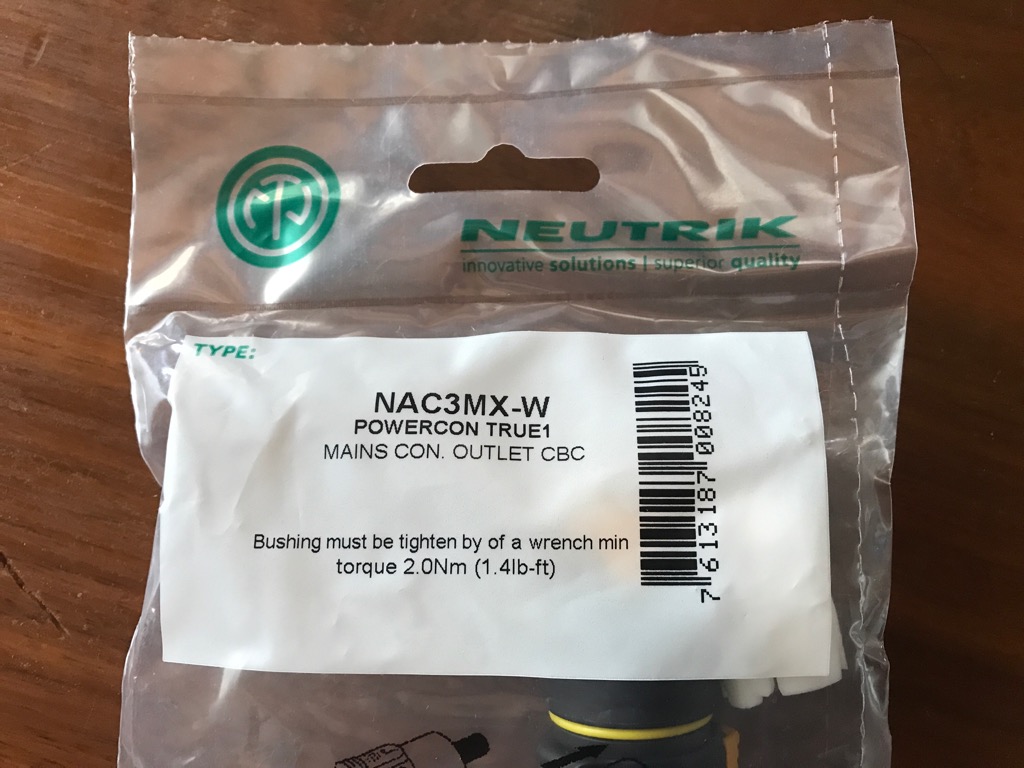

Through my search I came across a YouTube video where the poster replaced all his power cords with the Neutrik power connection system, which is the topic of my post.

I then searched around for local stock of these and found them at a rather decent price of R90 each (I see they have since gone up to R170 a piece - I probably bought up all their existing stock).

I subsequently purchased 20 male adapters and 5 female. The male adapter is permanently fitted to the power tool and the female adapter is required on the power cable side to the AC side socket.

Yesterday afternoon I got to work on the project and replaced 17 power cords so far and made up 3 leads.

I still have another 10 or so to go and thus need to purchase another 10 male adapters.

It makes very good sense to convert all your corded power tools and I only realized it about halfway through the batch I did yesterday. One can also make an extension cord with male on the one side and female on the other end.

My main tool cuboad looks a lot neater now and no more cords awkwardly wound around the tools.

Also no more euro adapters needed.

I?m happy that I did this, although I first had my reservations.

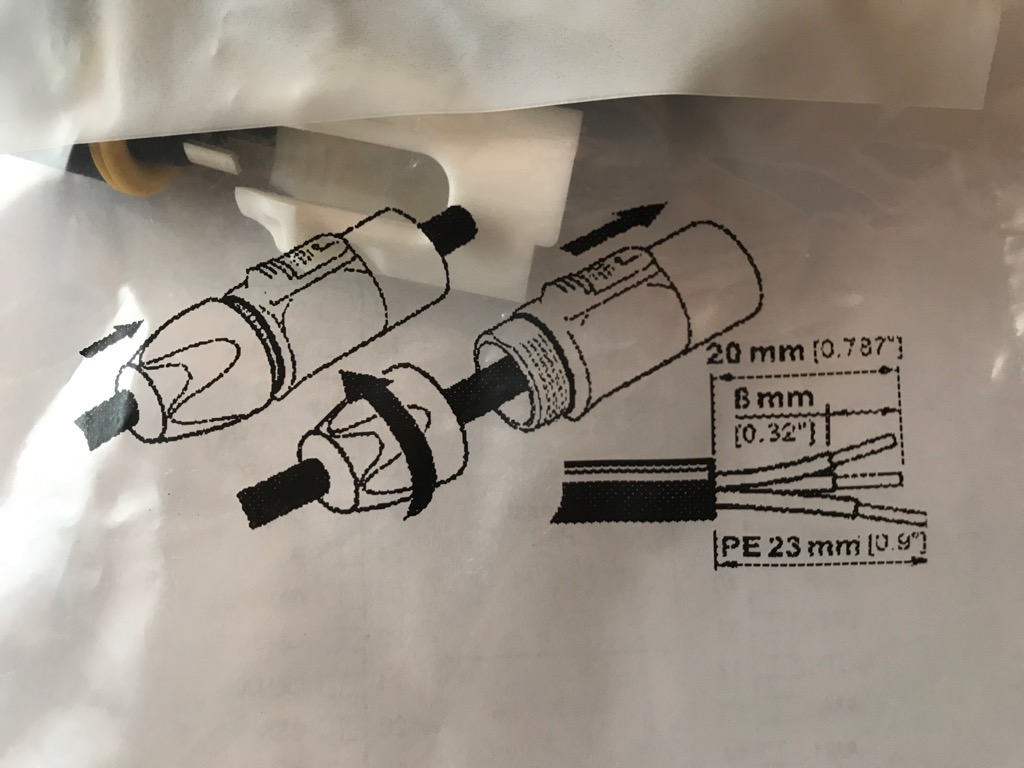

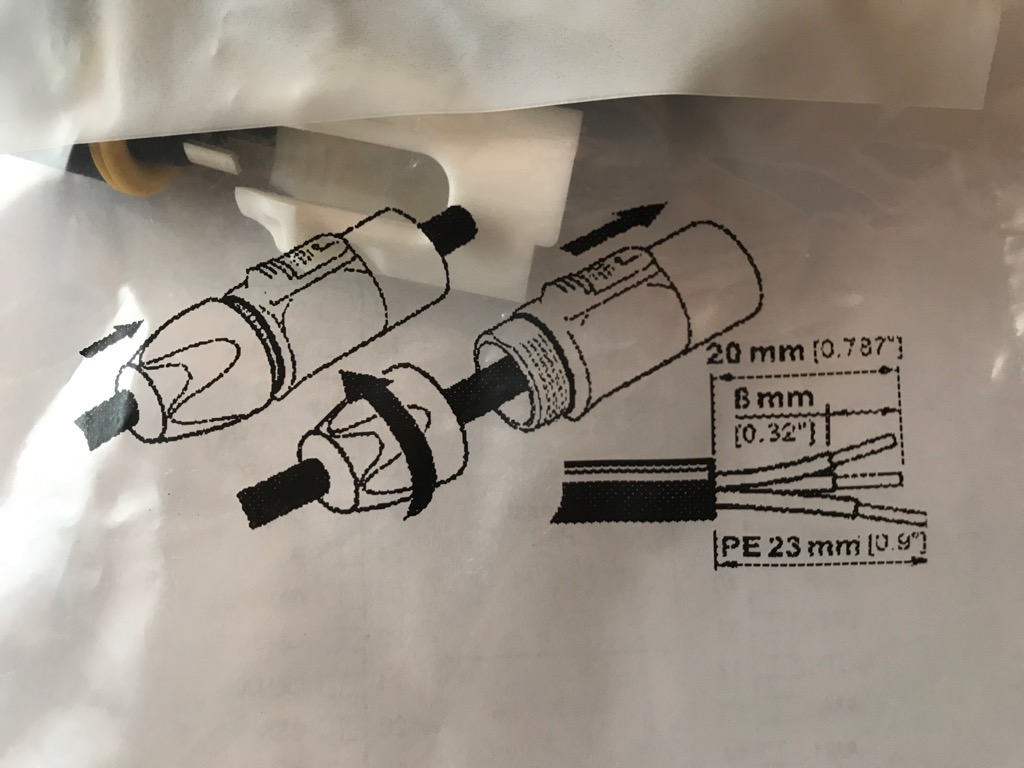

Its quick and easy to fit the Neutrik connectors and they have all three poles, namely Live, Neutral and Earth. The outer bits are all made of seemingly good plastics and the copper wires are clamped with a very neat metal mechanism, using Torx head grub screws. The biggest job is to prep/strip the cable.

The system makes for very secure and water tight connections.

Here are some ?after? pics (should have taken some ?before? too)

Through my search I came across a YouTube video where the poster replaced all his power cords with the Neutrik power connection system, which is the topic of my post.

I then searched around for local stock of these and found them at a rather decent price of R90 each (I see they have since gone up to R170 a piece - I probably bought up all their existing stock).

I subsequently purchased 20 male adapters and 5 female. The male adapter is permanently fitted to the power tool and the female adapter is required on the power cable side to the AC side socket.

Yesterday afternoon I got to work on the project and replaced 17 power cords so far and made up 3 leads.

I still have another 10 or so to go and thus need to purchase another 10 male adapters.

It makes very good sense to convert all your corded power tools and I only realized it about halfway through the batch I did yesterday. One can also make an extension cord with male on the one side and female on the other end.

My main tool cuboad looks a lot neater now and no more cords awkwardly wound around the tools.

Also no more euro adapters needed.

I?m happy that I did this, although I first had my reservations.

Its quick and easy to fit the Neutrik connectors and they have all three poles, namely Live, Neutral and Earth. The outer bits are all made of seemingly good plastics and the copper wires are clamped with a very neat metal mechanism, using Torx head grub screws. The biggest job is to prep/strip the cable.

The system makes for very secure and water tight connections.

Here are some ?after? pics (should have taken some ?before? too)