Just some pics to show the amount of work going into the manufacture of a set of Bentley Acoustics FR100 bookshelf speakers.

This is only the final finishing procedure, it excludes the basic cabinet construction which involves a CNC machine and plenty of glue!

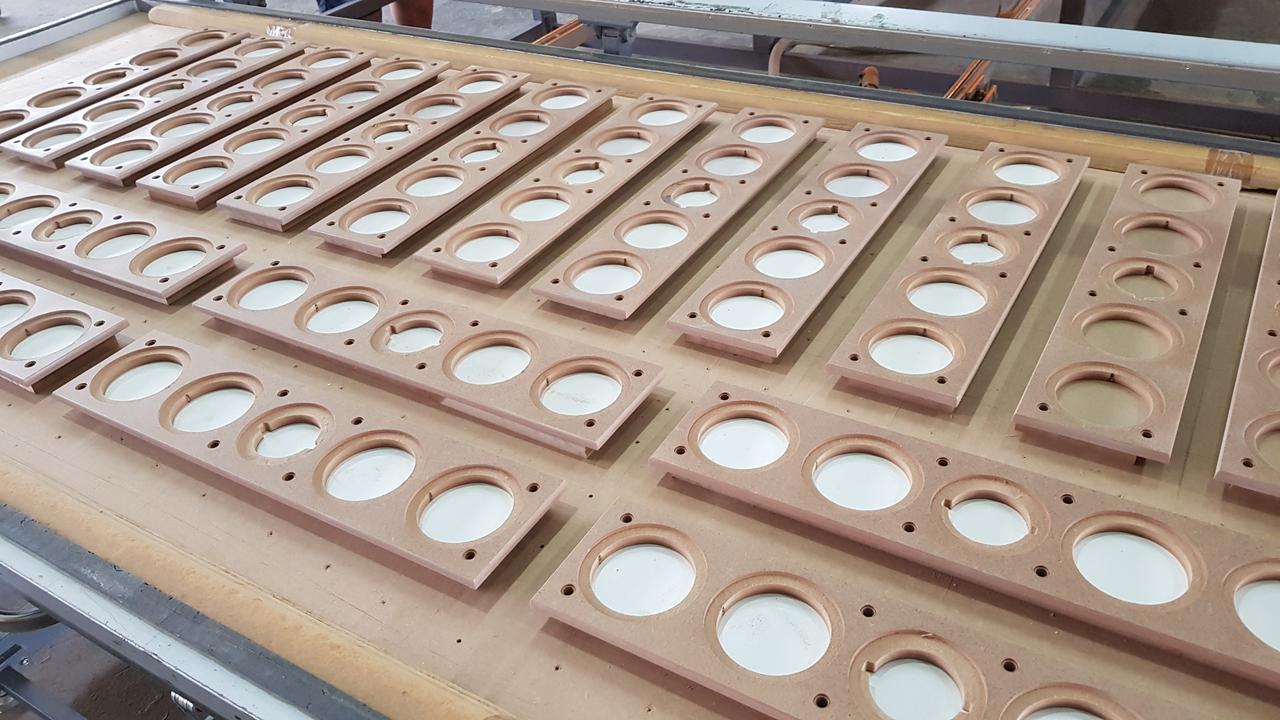

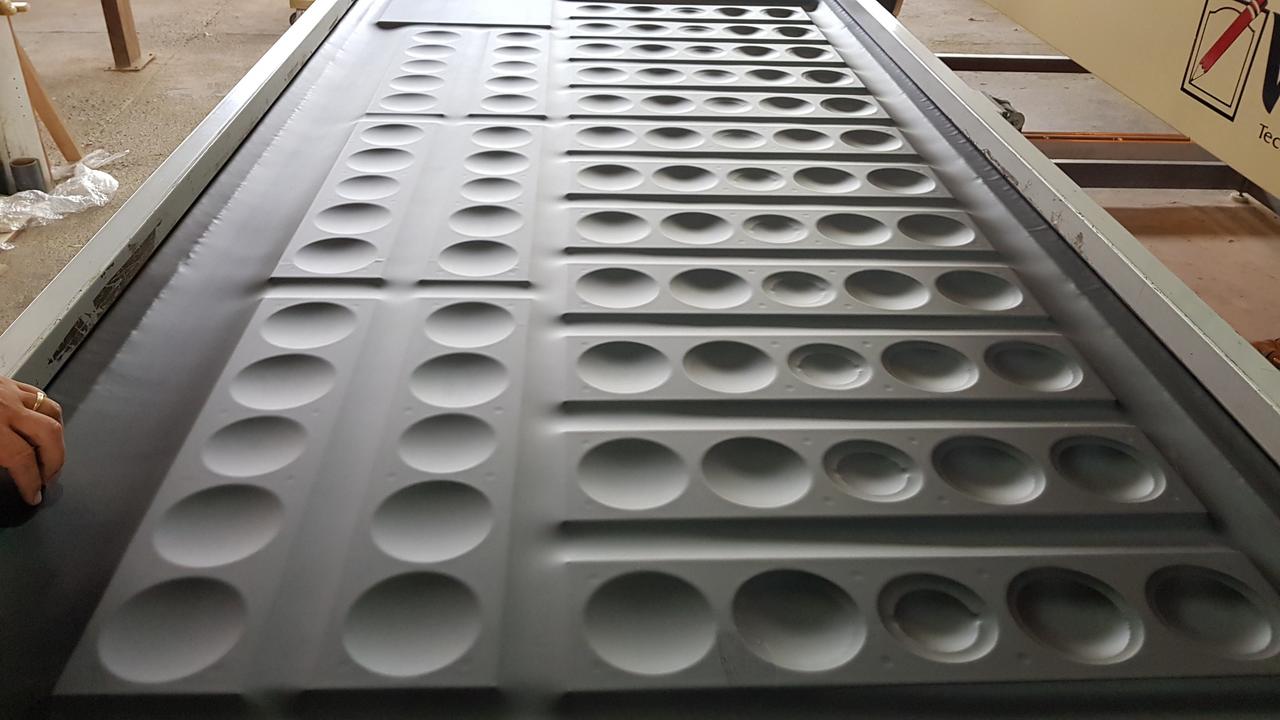

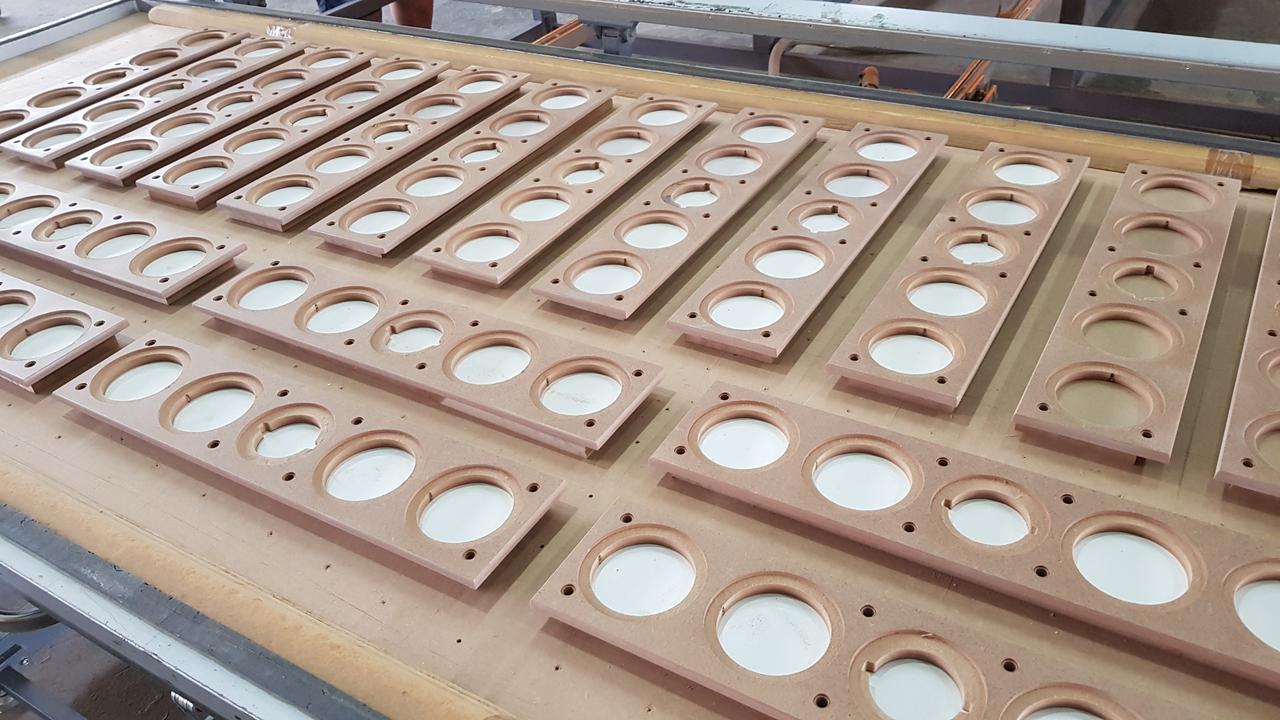

Grilles are also hand made and covered. Baffles (the face) is made by CNC and wrapped by a POSTFORM BAKE MACHINE - See final pics.

Keep in mind that every single speaker leaving the Bentley Workshop was finished by hand, every single one is unique and small imperfections is part of owning a hand made product. We do not have lifeless machines which assemble our products, instead we use real people, real hands, real passion and real love... Maybe this is what provides the little bit of soul which so many mass produced speakers lack. Like they say in the food industry : prepare your food with love and it will taste better!

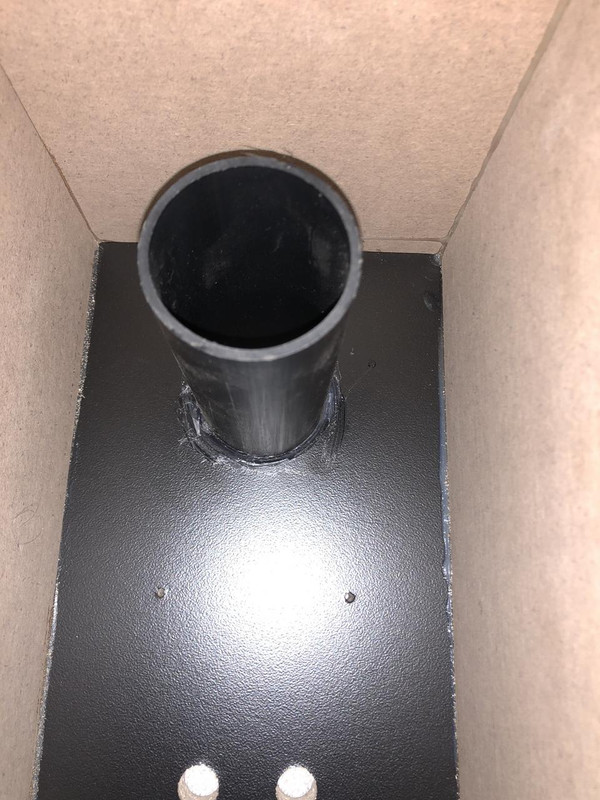

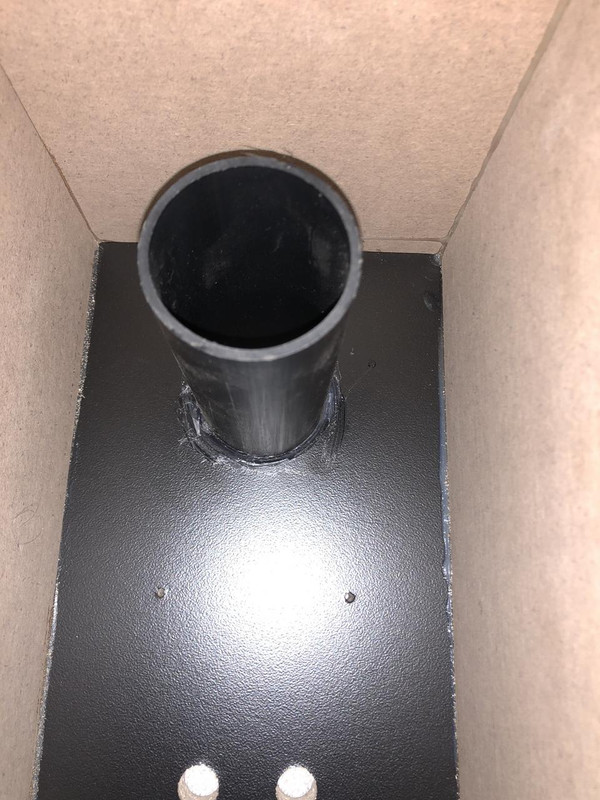

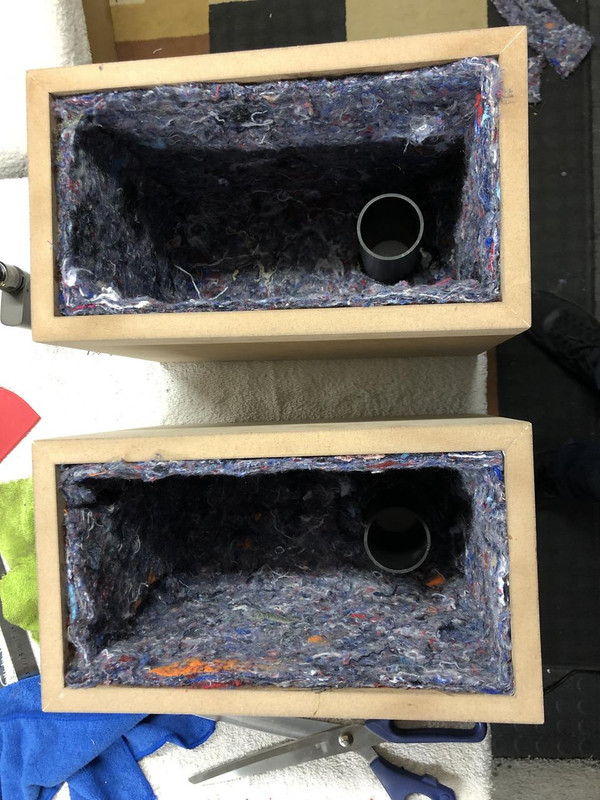

1st place the port.

Port secured

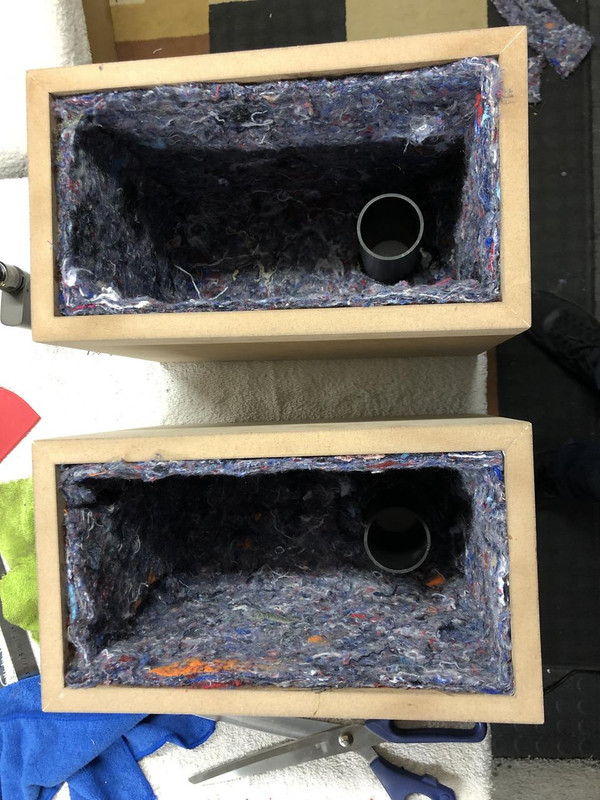

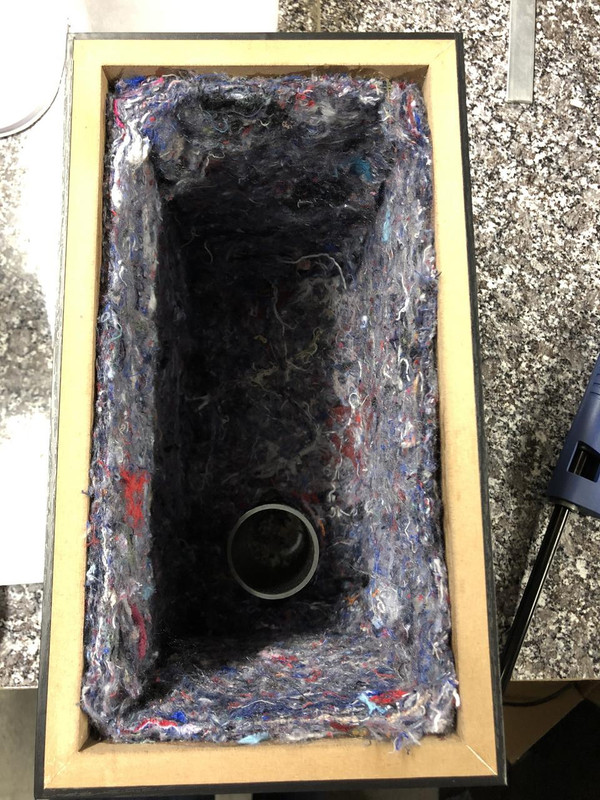

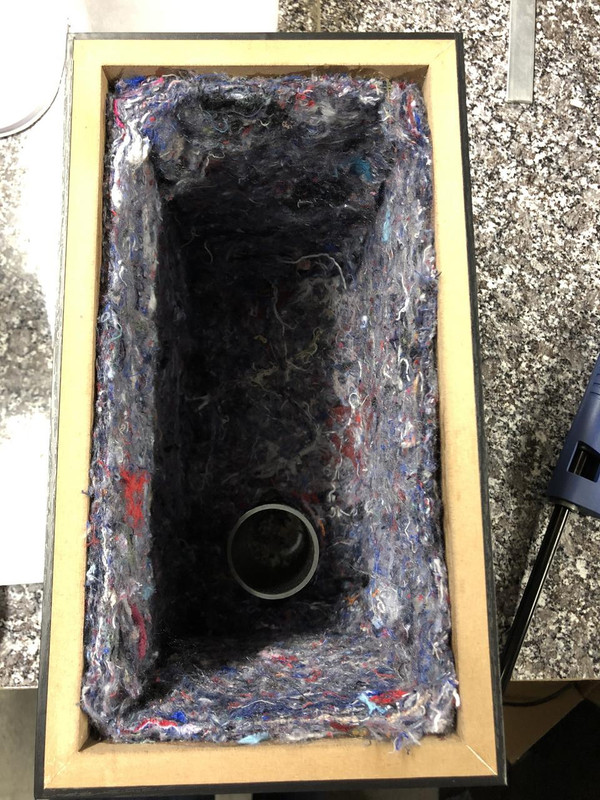

Glue blankets in place

Get those hands dirty!

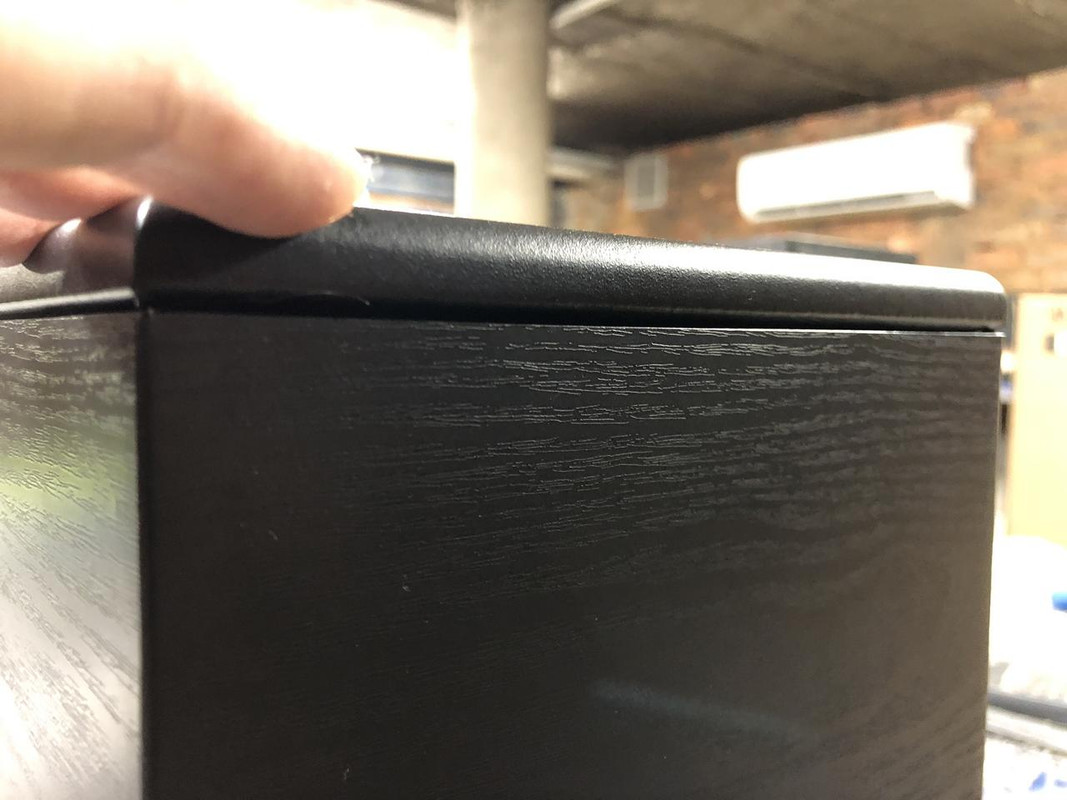

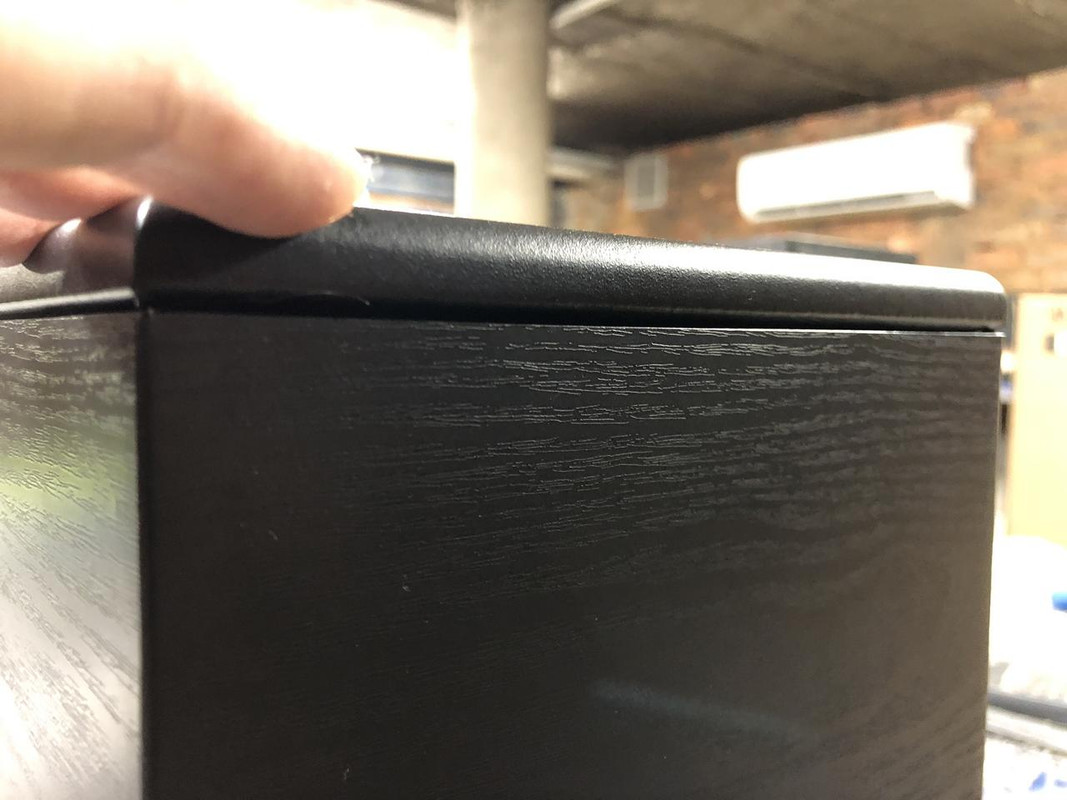

Starting the vinyl process...

Now to prep the edges..

Apply heat to make sure the vinyl sets.

Then the front.

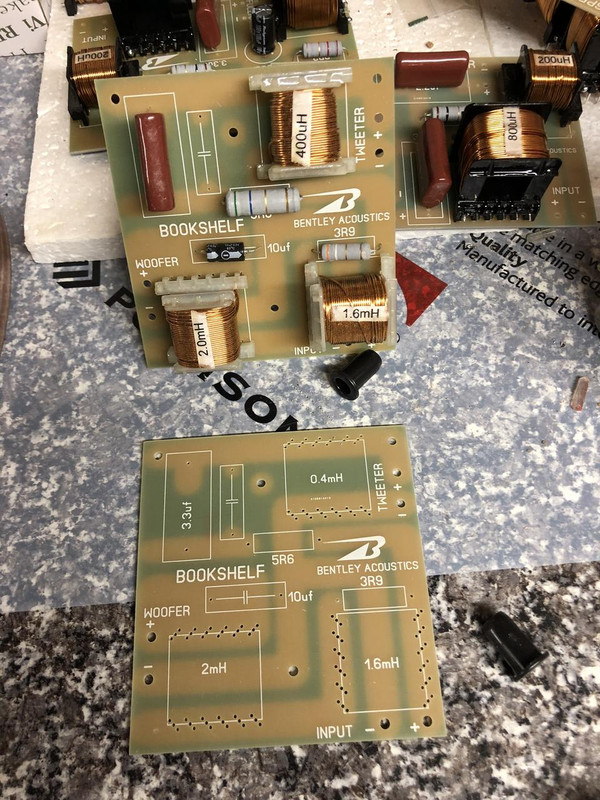

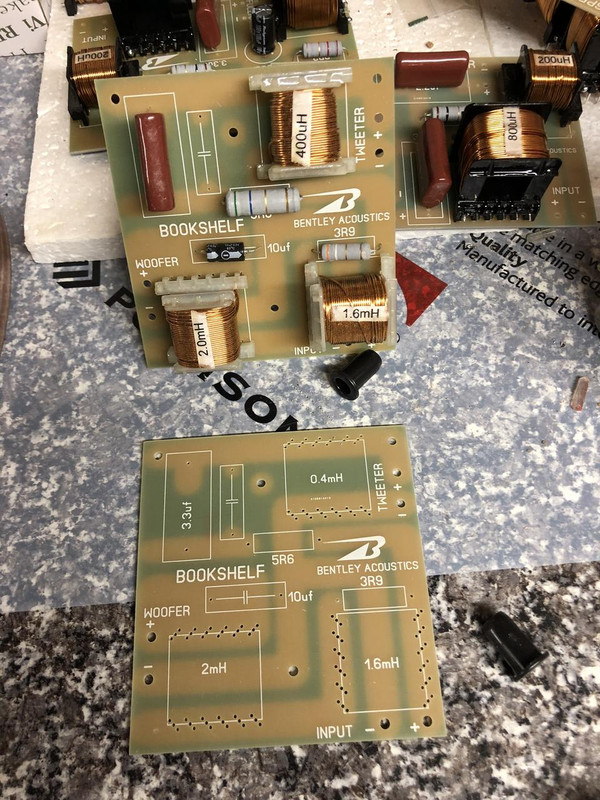

Assembling the crossovers (also by hand)

Secure the crossovers

Prepare to attach the baffle.

Clamping

Attach terminals

Attach drivers

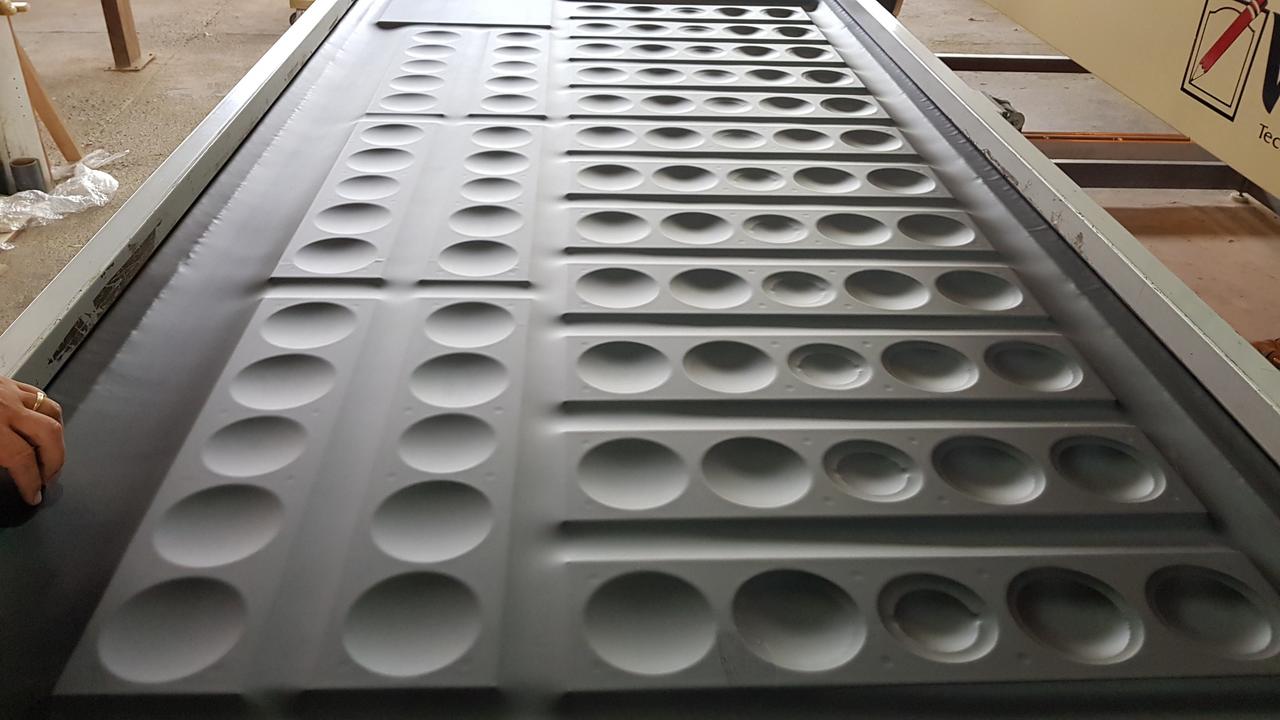

Baffle baking

Clean, test, box and ready for their new home.

https://www.bentleyacoustics.com/fr100

This is only the final finishing procedure, it excludes the basic cabinet construction which involves a CNC machine and plenty of glue!

Grilles are also hand made and covered. Baffles (the face) is made by CNC and wrapped by a POSTFORM BAKE MACHINE - See final pics.

Keep in mind that every single speaker leaving the Bentley Workshop was finished by hand, every single one is unique and small imperfections is part of owning a hand made product. We do not have lifeless machines which assemble our products, instead we use real people, real hands, real passion and real love... Maybe this is what provides the little bit of soul which so many mass produced speakers lack. Like they say in the food industry : prepare your food with love and it will taste better!

1st place the port.

Port secured

Glue blankets in place

Get those hands dirty!

Starting the vinyl process...

Now to prep the edges..

Apply heat to make sure the vinyl sets.

Then the front.

Assembling the crossovers (also by hand)

Secure the crossovers

Prepare to attach the baffle.

Clamping

Attach terminals

Attach drivers

Baffle baking

Clean, test, box and ready for their new home.

https://www.bentleyacoustics.com/fr100